Details |

|

|---|---|

| max. wheel diameter | 275 mm |

| gear width | 55 mm |

| max. module | 6,5 |

| min. module | 1,5 |

| weight | 13000 kg |

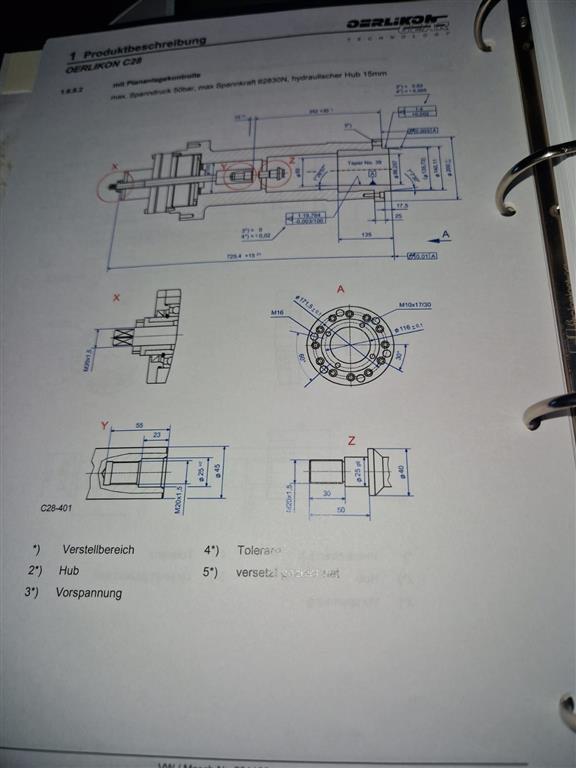

OERLIKON C28

- All categories

- Metal Processing

- Gear cutting machines

- Bevel Gear Generator - Spiral

OERLIKON C28

Offer details |

|

|---|---|

| Stock-No. | 1113-235121 |

| Type of machine | Bevel Gear Generator - Spiral |

| Company | OERLIKON |

| Type | C28 |

| Year of manufacture | 1998 |

| Type of control | CNC |

| Control name | Siemens 840C |

| Storage location | Butzbach |

| Country of origin | Germany |

| Delivery time | immediate, as agreed |

| Freight basis | FCA |

| Price |

Description

Face Milling-Single Part Process

Continuous process: The workpiece and tool (usually Spiron) rotate at the same time, and all teeth are created in one operation at the same time. Knife head has several knife groups (not arranged in a circle) Parallel tooth Conical tooth tip surface

Single Item procedure: The workpiece is stationary and the tool (usually Arcon) rotates and cuts a tooth by immersing the tool. Once a tooth is cut, the tool moves out of the tooth again, the workpiece divides by one tooth width and the next tooth is cut until all teeth are finished. Knife head has arranged all knives in a circular path. Conical tooth height Parallel tooth head surface

C28 can do both, wheel + pinion. However, a C28 must be “prepared” for the individual part procedure. I.e. direct measuring system + part gear brake, workpiece axis + license file for the production of individual parts.

Machine request

Provider

HD Werkzeugmaschinenhandel GmbH

Robert-Bosch-Str. 1

35460 Staufenberg1

Telephone: +49 6406 83141-0

Fax: +49 6406 83141-2

Email: hdgmbh@hd-gmbh.com

www.hd-gmbh.com